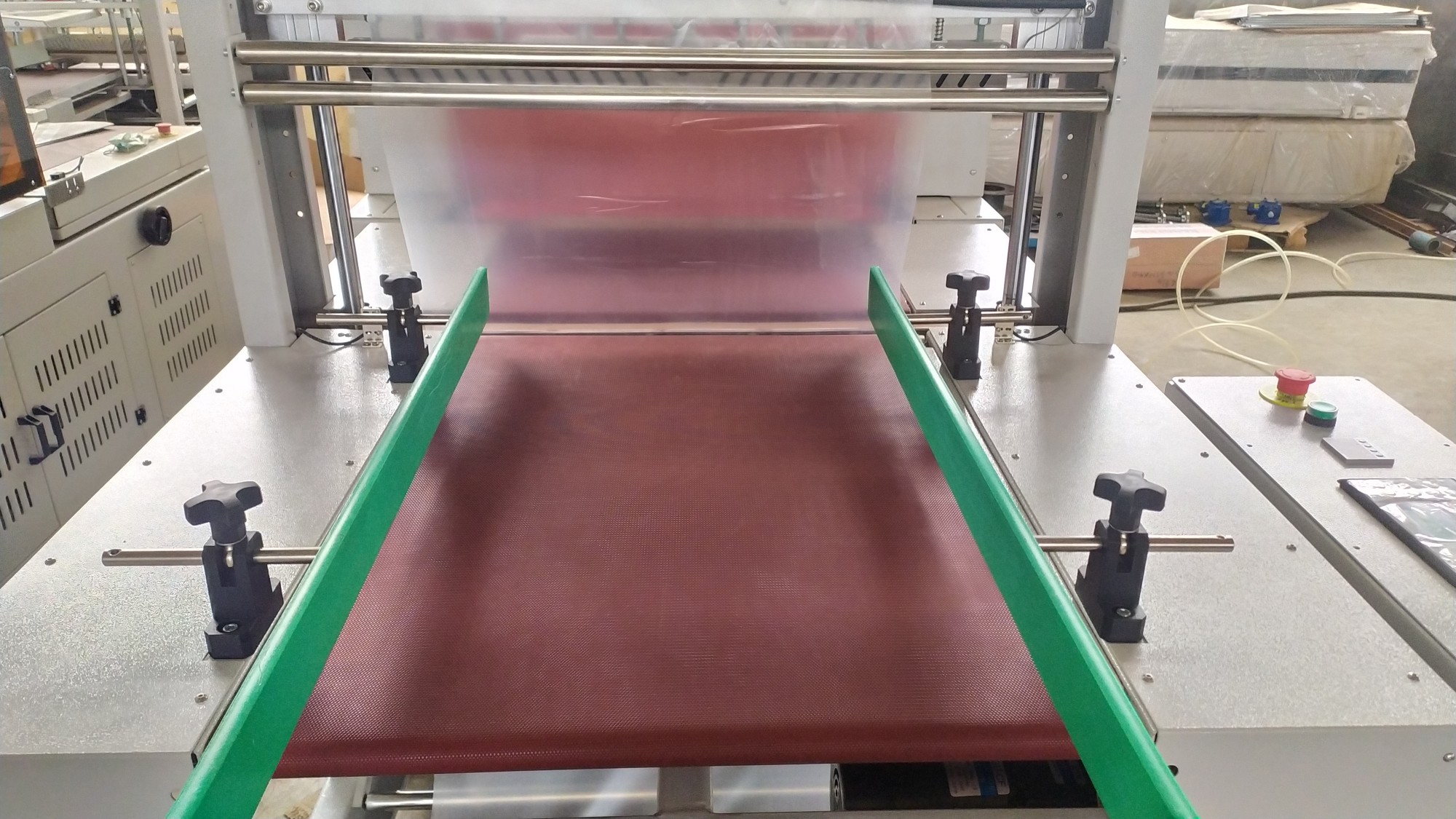

Sleeve Wrapper Bundler is Designed for Producing Transit Packs in PE Shrink Film. Two Rolls of Flat PE are Sealed Producing a "Curtain" of Film. The Pack Travels into this "Curtain" of Film Producing a Sleeve Around the Pack which Shrinks Tightly in the Shrink Tunnel.

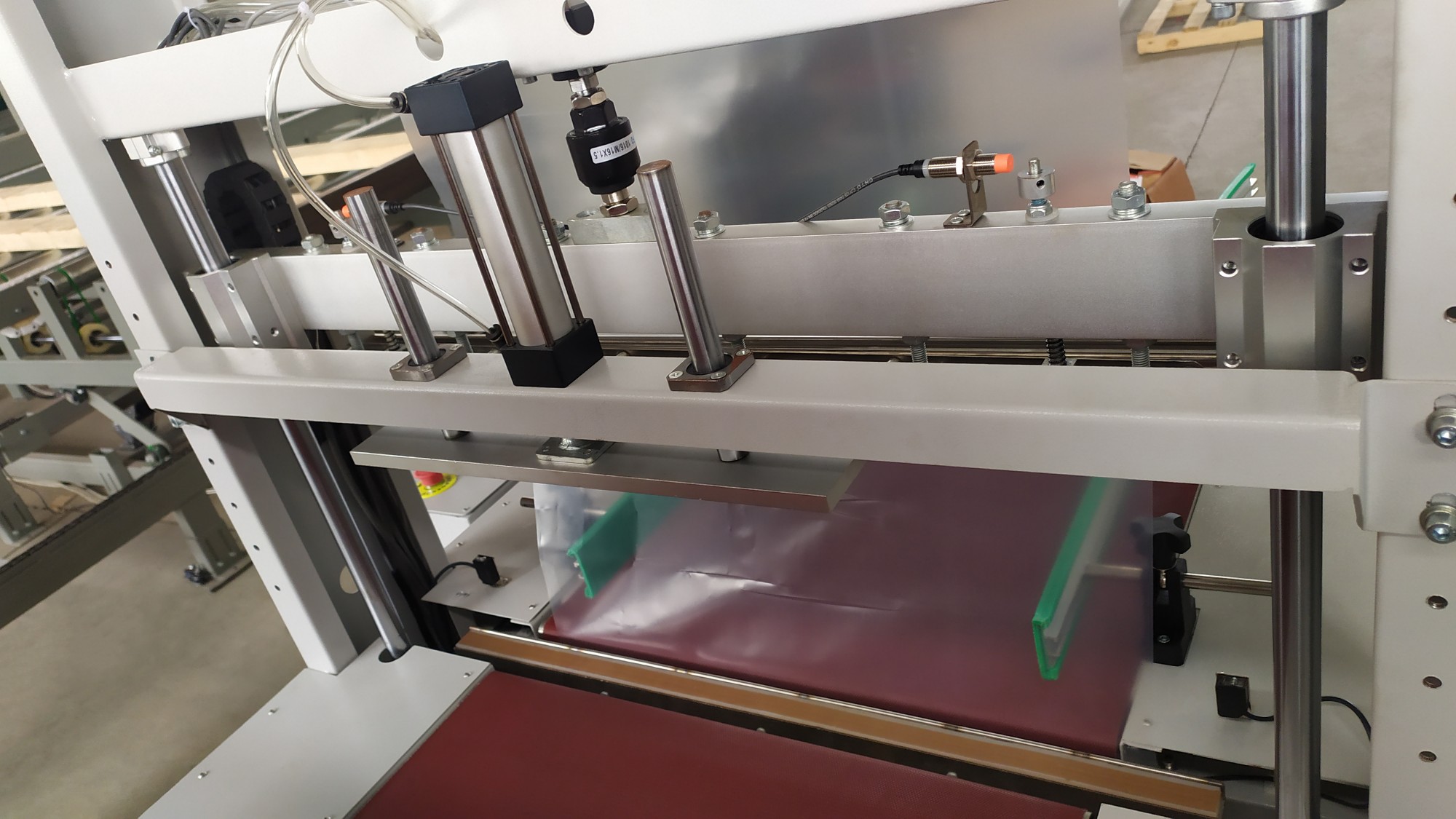

The UXF-6030A Straight Line Automatic Sleeve Wrapper Bundler Comes Standard with a Straight Line Infeed Belt Conveyor which can Operate Totally Automatically Receiving a Continuous Stream of Packages, a 650 mm Long PTFE Coated Sealing Bar with 300 mm Max. Packing Height and a High Output Up to 15 Pcs/min.

Stand-alone Using or Intergrated to Your Existing Production Line, This Model Can be an Ideal Solution for Individual Items Such as Cartons, Bottles, Cans, Boxes and Jars Continuously Sleeve Wrapped into One Manageable Package.

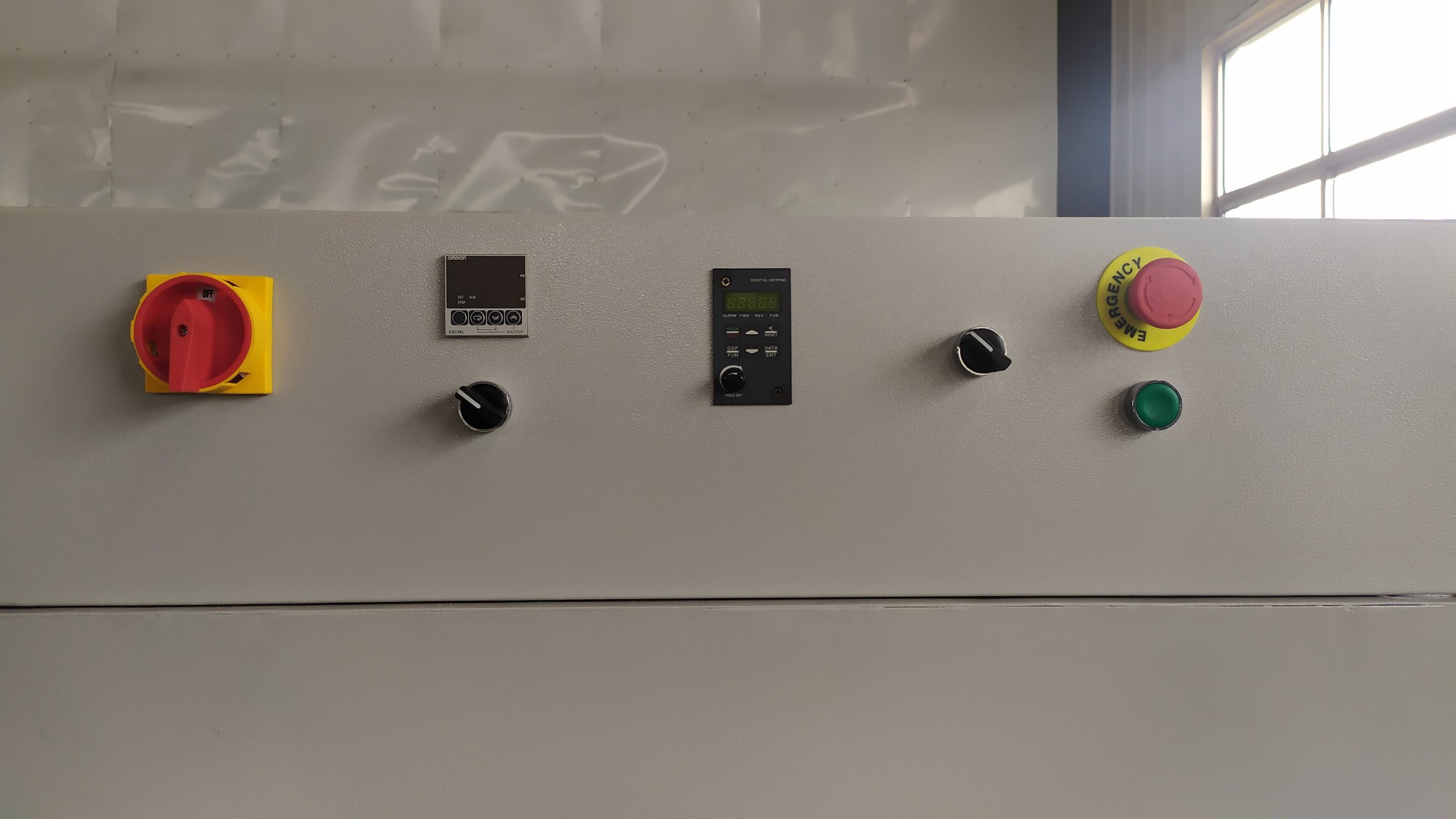

An Optional Extra is the UR-6040AE Heat Shrink Tunnel which can be Attached to the UXF-6030A Straight Line Automatic Sleeve Wrapper Bundler for Shrinking the Wrapped Product of PE Shrink Film The UR-6040AE Heat Shrink Tunnel Comes Standard with a L 1800 mm x W 600 mm x H 400 mm Sized Chamber, Digital Read-Out Makes it Easy to Set Up the Perfect Shrink Chamber Temperature Up to 200ºC, Energy Saving Automatic Thermostats, 12 m/min Adjustable Conveyor Speed and Cooling Fan for PE Film Rapid Cooling Down.

Specifications

Model | UXF-6030A Sleeve Wrapper Bundler | UR-6040AE Heat Shrink Tunnel |

Packing Size Max. | L + H ≤ 600 mm; |

W 400 mm × H 300 mm |

Sealing Bar | 650 mm | / |

Chamber Size | / | L 1800 mm × W 600 mm × H 400 mm |

Worktable Height | 750mm with 50mm adjustable feet | 750 mm with 50 mm adjustable feet |

Load Capacity Max. | 30 kg | 50 kg |

Efficiency | 0 - 15 pcs/min | 0 - 12 m/min, variable |

Film | PE shrink film in 40 - 120 um thickness | PE shrink film in 40 - 120 um thickness |

Air Supply | 0.5 - 0.7 Mpa | / |

Voltage | 220 VAC 1 ph 50/60 Hz | 380 VAC 3 ph 50/60 Hz |

Power | 2.5kw | 10 kw |

Machine Size | L 1820 mm × W 1300 mm × H 2150 mm | L 2800 mm × W 960 mm × H 1670 mm |

Machine Weight | 500 kg | 420 kg |